Introduction

•By

achieving Practical knowledge it is possible to apply the theoretical knowledge

in the technical field. For any technical education, practical experience is

almost equally necessary in association with the theoretical knowledge. The

Industrial attachment is most effective process of achieving the practical

experience. It provides us sufficient practical knowledge about production,

management, productivity, evaluation, work study, efficiency, Industrial

management, production planning & control, Production cost analysis,

inventory control, purchasing, utilities and Maintenance of machinery and their

operation technique etc.

•

•Industrial

attachment is an essential part of four years B.Sc. in Textile Engineering

course of Pabna Textile Engineering

College under the University of Rajshahi. We had the opportunity to perform the industrial

attachment with “GMS Composite Knitting Ind. Ltd”. During two month

long attachment, we studied the man, machine, material aspects of the knitting

section, Dyeing section, quality control section, planning section, grey fabric

inspection, finished fabric inspection, finishing section and merchandising

section of the factory. According to our studies there we have prepared the

following report and would like to present.

Organ Gram of Manpower in GMS….

enior General Manager

General Manager

•

Deputy General Manager

Senior Manager

Manager

Deputy Manager

Assistant Manager

Senior Executive

Executive

Junior Executive

Supervisor

Helper

Operator

Different Sections of

GMS…

●Yarn Dyeing

Knitting

● Batch Preparation

● Laboratory

●

Dyeing

● Finishing

●ETP & WTP

BOILER & GENERATOR

Dyeing

Here

bleaching, scouring & dyeing is done.

Temp: cotton 60c,polystar 130c,blended p\c(65\35) 90c.

1.sample

dyeing:

No of

m\c=9

Company: Galvanin:-no:4capacity:10kg each;

KTM

MAKINA: no of m\c:5 4 m\c capacity 35 kg each & one is 10kg

2.Batch dyeing:6+1(NUM)

Company

name:

CaLvanin:6 total capacity=2500kg

KTM

MAKINA:1 capacity=1250kg

Total yarn dyeing capacity=7500kg\day

Hydro Structor

It is a process for removing water from package as possible

by applying pressure.

No of

m\c:2

Capacity:

35kg time: 6min

Dryer

It is a

process for dry the yarn package by heat or radio frequency

No of

m\c: 2

Company: Galvanin& Stalam

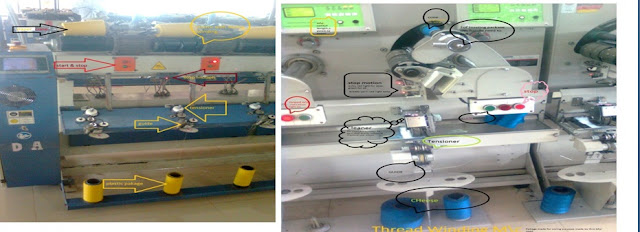

1.Random winding:

It is

rewinding process to convert yarn plastic package to paper package for the

suitable use of this package at loom\knitting m\c.

No of

m\c: 8

Wt of pakage: Cheese

5 kg& cone 1Kg

Types of

M\c:3

1.MilHan:

4(NUM)

Spindle:

24*2

2.Thread winding:

It is a rewinding

process to convert yarn from 1kg cone to 100g cone for swing purpose.

Types of m\c:2

কোন মন্তব্য নেই:

একটি মন্তব্য পোস্ট করুন