Process

Flow chart of Knitting (Circular):

Knitting of the Fabric

Withdraw the Rolled Fabric and Weighting

Sample Fabric

Design analysis

Machine Selection

Machine Setting for

the Required Design

Knitting of the Fabric

Conform Required

Quality

Withdraw the Rolled Fabric and Weighting

Inspection

Delivery

Types

of Raw Materials….

Types of fabric

Machine

Description

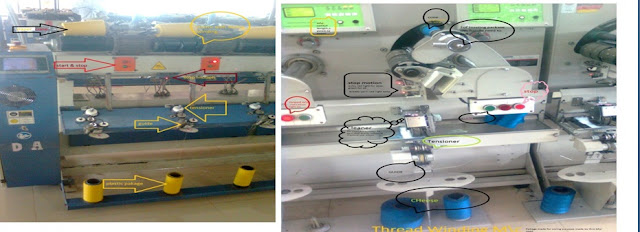

DIFFERENT PARTS & THEIR FUNCTION

OF CIRCULAR KNITTING MACHINE:

Creel: Creel is a part of knitting

machine. Here yarn package are store and ready to feed in the machine.

VDQ pulley : It control the quality of the

product. Altering the position of the tension pulley changes the G.S.M. of the

fabric. If pulley moves towards the positive direction then the G.S.M is

decrease. And in the reverse direction G.S.M. will increase.

Pulley belt: It control the rotation of the MPF

wheel.

Brush: It clean the

pulley belt.

Tension disk: It control the tension of the

supply yarn.

Inlet &Outlet stop motion: It stops the machine when yarn

breaks.

Yarn guide: It helps the yarn to feed in the

yarn feeder.

Feeder ring: It is a ring where all feeders are

placed together.

MPF: It gives the positive feed to the

m/c.

Feeder: It helps yarn to

feed into the m/c.

MPF wheel: It control the speed of the MPF.

Needle: It helps the yarn to create a loop

and by this way fabric are produced

Needle Track: Where all needle are placed

together in a decent design.

Sinker: It helps to loop forming, knocking

over & holding down the loop.

Cam: It is a device which converts the

rotary m/c drive into a switable reciprocating action for the

needles & other elements

Sinker ring: It is a ring where all sinkers are

placed together.

Lycra attachment: lycra is placed here & feeding to the

m/c.

. Lycra stop motion: It stops the m/c when the lycra

is break.

Cam box: Where the cam are set horizontally.

Inverter: It

is the heart of the circular knitting m/c. It control the speed of the m/c.

. Cylinder/Dial: Needle track are situated here.

Screen: It is a digital screen which show

the all m/c information & we can give command to the m/c.

Cylinder balance: It helps the cylinder to set in a

proper alignment.

WPI: Wales per inch is called WPI.

CPI: Course per inch is called CPI.

Needle

calculation:

◊ Single jersey

circular knitting machine needle = ∏DG

◊ Rib/Inter lock

/Double jersey circular knitting machine needle

= ∏DG×2 (two needle

bed is here)

◊Single bed flat knitting m/c’s

needle = width× gauge

◊ V bed flat

knitting m/c’s needle = 2× width× gauge

Here, D = cylinder

diameter ,G = Machine gauge ,Needle pitch = 1/G.

◊ GSM: Grams per square meter of the fabric are called GSM.

◊ GSM = {WPI× CPI × (39.37)2×stitch length

(mm) ×Tex /1000× 1000} g/m2

◊ Stitch density = (WPI × CPI) inch-2

= (WPC ×CPC) cm-2

◊ No of sinker = No of needle

◊ No Wales =No of needle

◊ No of course = No of feeders

=No of yarn (per

revolution of cylinder)

◊ Course per minutes = No of feeders

×cylinder rpm

◊ Course length = yarn required for

each course.

= No of needle ×

stitch length

◊ Fabric width = wale spacing ×Total

no of Wales

= (1/WPI ×No of Needles)

inch

= (No of Needles/WPI×

39.37) meter

- For single

jersey fabric = (∏DG/WPI×39.37)

meter (open width)

=(∏DG/WPI×39.37)

meter/2(Folded/Tubular width)

- For double

jersey fabric = (2 × ∏DG/WPI×39.37)

meter (open width)

= (2×∏DG/WPI×39.37)

meter/2(Folded/Tubular width).

◊ Fabric Length =Course spacing ×Total course pr hour

= {(Feeder× cylinder

rpm× 60)/CPI} inch/hour

= {(Feeder× cylinder rpm× 60)/CPI ×39.37} m/hour

Typical

Parameter For Knit Fabric:

Sample Design& Cam Arrangement

Knitting Fabic Fault Cause and remadies

Method

of Increasing Production

—1. By increasing m/c speed:

Higher the m/c speed faster the movement of

needle and ultimately production will be increased.

—2. By increasing the number of feeder:

If the number of feeder is increased in the

circumference of cylinder, then the number of courses will be increased in one

revolution at a time.

—3. By using machine of higher gauge:

The more the machine gauge, the more the

production is. So by using machine of higher gauge production can be increased.

—4. By imposing automation in the m/c:

a) Quick starting & stopping for

efficient driving system.

b) Automatic m/c lubrication system for

smoother operation.

c) Photo electric fabric fault detector

—5. By imposing other developments:

a)Using creel-feeding

system.

b)Applying yarn supply

through plastic tube that eliminates the possibilities of yarn damage.

c)Using yarn feed

control device.

d)Using auto lint

removal.